Industrial Microwave Solutions in the Plastics Industry

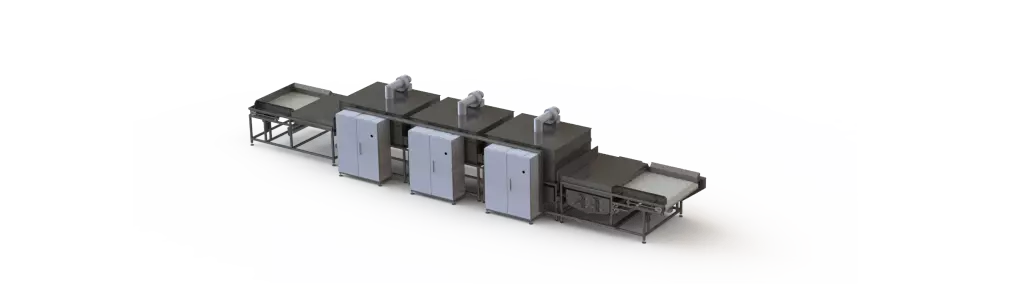

MET Industrial Microwave Dryers, specially designed for the plastics industry, offer Plastics Industry Microwave Solutions that enable you to achieve high performance and efficiency. Our industrial drying systems fully meet your business with their customizable structures and deliver quality results.

Industrial Microwave Solutions in the Plastics Industry

MET Industrial Microwave Dryers, specially designed for the plastics industry, offer Plastics Industry Microwave Solutions that enable you to achieve high performance and efficiency. Our industrial drying systems fully meet your business with their customizable structures and deliver quality results.

Error Rate

Reduction

Increased

Quality

Energy

Efficiency

Productivity

Value-Added

Labor

Decline

Plastic Industry Solutions with Met Advanced Technology Microwave Ovens

The use of industrial microwaves in the plastics industry is quite widespread, especially in the melting, drying and shaping of plastics. Industrial microwave is highly effective in processing plastics that do not melt at high temperature. In this way, the process of melting plastics is faster and less energy is consumed. Therefore, the use of industrial microwaves is important for reducing production costs in the plastics industry.

In addition, industrial microwave is also used in the drying process of plastics. Keeping plastics moist during the production process can lead to loss of quality and spoilage of products. By using industrial microwave, it is possible to quickly remove the moisture from plastics. Thus, the quality of the plastics is maintained and the production process becomes more efficient.

Finally, the use of industrial microwaves is also highly effective in shaping plastics. The temperature and consistency of plastics can be controlled using industrial microwaves. This ensures that the plastics are in the desired shape and size. Industrial microwave can also be used in molding processes of plastics.

In general, industrial microwave is a widely used technology in the plastics industry to speed up the production process, save energy and improve product quality.

Heating Plastics

In the plastics industry, state-of-the-art microwave capabilities are used for preheating drying, polymerization, compounding, forming, shrinkage, recycling and other thermal applications.

Benefits of Microwave Heating

Due to the excellent heating uniformity selective heating of the solvents and minimal impact on the substrate, energy savings of around 30% are achieved for a given application. Despite their poor thermal conductivity, cast products and profiles with larger cross-sections can be processed. The procedure is light and product-friendly when performed at moderate outside temperatures, reducing overheating in certain applicable cases. Its flexibility allows accurate process driving within the volume, reducing the material’s exposure to damaging stress and strain.

Dielectric Heating

Plastics are often very poor conductors of heat. Due to the thermal gradient that can degrade the qualities of the product, conventional heating is the only method that allows energy input. The volume is affected by the microwave field, which is independent of conductivity.

Plastic Drying

Drying is probably the most common in the plastics industry. The method differs significantly from normal drying and offers unique advantages, such as maintaining the same moisture and heat gradient, water pump and capillary effects, and reducing top crust development. The design is quite universal and makes it possible to process various forms, parts or powder materials without having to change the line or the chamber in a complex way. The design idea is largely quite similar. Drying hygroscopic plastic granules is a very important application, especially before extrusion.

Our Services for the Plastics Industry

As Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specifically for the plastics industry.

Our Services for the Plastics Industry

As Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specifically for the plastics industry.

Industrial Microwave Oven Solutions

Advanced, High-Tech Microwave Oven Systems

Discover Our Next Generation Innovative Products

Industrial Microwave Oven Solutions

Advanced, High-Tech Microwave Oven Systems

Discover Our Next Generation Innovative Products

Let’s Design a Custom Project for You

Let us develop and propose customized projects for your sector, product and needs.